Cheese Buying and Distribution

It’s a long road from ‘Farm to Fridge’ the journey and industry behind it is fascinating even for the amateurs. We’ve gathered all the resources you need here.

101 guide – Buying and Distribution | Chapter one

What is Buying and Distribution?

Cheese Buying and Distribution

Traditionally, cheese was made by farmers as a way of preserving milk and for personal subsistence. Any surplus cheese would have been sold at the farm gate, or where possible, taken to a local market to be sold to the local community.

The History of Cheese Industry

In the 18th Century, advancements in agricultural technology and science, along with the major land enclosures, changed farming completely, in turn affecting dairying and cheesemaking.

By the 19th century, British Cheesemaking was shaped by the demands of feeding the growing industrial towns as well as the wider Empire. In line with European communities, suburban dairies were established to process the milk from rural farms arriving by train, and it became more commonplace to gather milk from different sources to make larger quantities of cheese. Cheese production in the UK at this time was driven by demands on productivity and on the logistics of moving large quantities of perishable goods over increasingly large distances.

The wars and subsequent economic turbulence of the early 20th century was felt by dairy farmers and cheesemakers acutely. Economic difficulties, government regulated milk pricing and rationing had a major impact on cheesemaking, and by the 1950’s, the British artisan cheese industry had almost died out.

In 1954, rationing was stopped, and the industry embarked on its recovery, spearheaded by Major Patrick Rance and the opening of Britain’s first cheese shop.

The Global Cheese Industry

International trade, improved logistics, advances in technology and consumer demand have fuelled the industry: the global cheese market is projected to grow from $123.87 billion in 2021 to $161.23 billion by 2028, at a CAGR of 3.84% in forecast period, 2021-2028 (https://www.fortunebusinessinsights.com/cheese-market-104293).

To compete in this burgeoning market, an efficient, effective supply chain is increasingly key to success and will have an impact on pricing strategy. To understand the options available, it is necessary to understand the key elements in the buying and distribution model.

How is Cheese Bought & Transported?

The cheese supply chain starts with the cheesemaker and where they procure their number one ingredient, ie. milk. A small farmhouse producer or artisan cheesemaker will use their own milk, or buy in milk from a local farm, to make small batches of cheese. A co-operative, such as Long Clawson Dairy, makes cheese from milk supplied only by a cooperative of dairy farmers, whilst an industrial creamery, such as Cathedral City operate from a factory and draw their milk from a large number of farms and can generally command a much lower price on the milk.

From Farm to Fridge

Once the cheese is made, the Supply Chain to reach the final consumer can vary by the number of steps required. There are several contributors to the decision-making process, but the key ones are:

Cheese type, make & maturity of the cheese

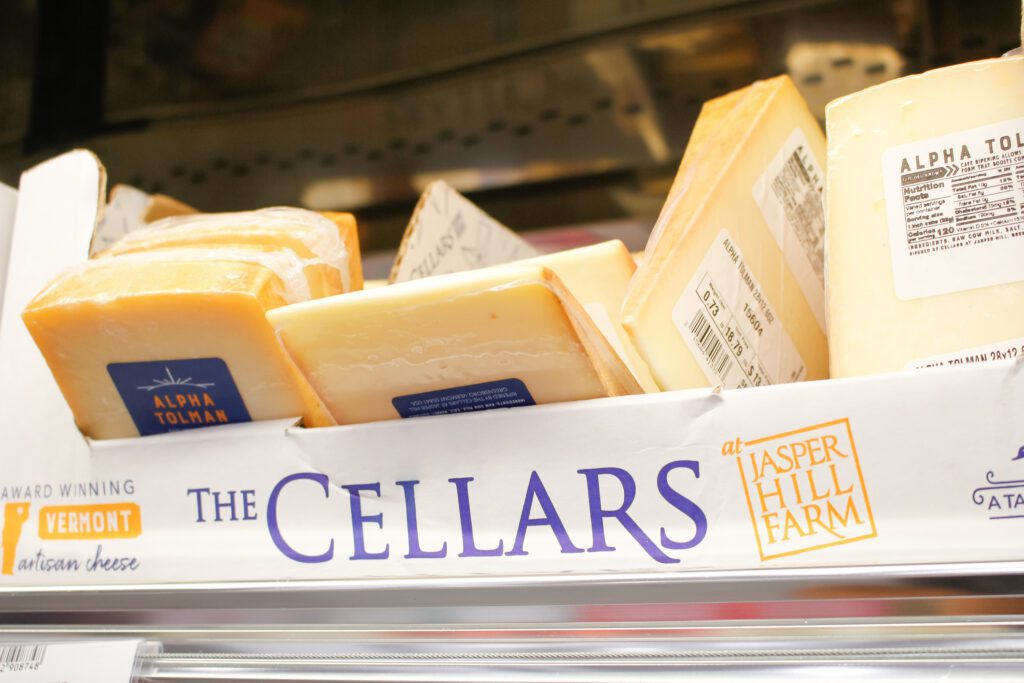

Fragility is a key factor in some cheeses, particularly Geotrichum candidum cheeses, where the rind is fragile, and can break by being pressed or knocked. In this case, producers may charge more to compensate for the higher wastage. Conversely, an aged cheddar may be destined for distant shores that a young cheese wouldn’t survive the journey to. An important factor to consider when making cheeses intended for ageing is whether or not the maker has the expertise and space to ripen their own cheeses or will it be sent to an affineur to age?

Required sales format of the cheese

Thinking about the packaging and display of block cheddar destined for supermarket sale, this will need an element of processing; it will be cut and vacuum packed in thick plastic before leaving the factory, to ensure a longer shelf-life that can withstand cold chiller cabinets and lots of customer handling. Compare that to a traditional, clothbound cheddar sent out to be displayed in a cheesemonger’s, open and visible to the customer, not only so they can see the properties of the cheese and perhaps even sample it, but also so that the cheesemonger can keep an eye on the condition of the cheese and cut to order.

Country where the cheese is made versus country of customer

International trade adds levels of complexity to any distribution chain. As well as the physical method of crossing borders, eg. road, sea or air, consolidators are required to collect the cheese from the maker and then distributors in the destination country are needed to get the cheeses to their destination. Import tariffs add additional costs and customs clearance require an administration resource.

Route to market – direct or indirect?

If the cheesemaker decides to use a wholesaler to get their cheeses to the consumer, their profit margins will generally be lower, as they are effectively paying the wholesaler to sell their cheese. However, selling direct, eg. via a farmers’ market, will incur wastage costs as sampling is often a large part of this the sales process. Online sales, which increased ten-fold during the pandemic as consumers struggled to buy from traditional shops is now a mainstay of many producers and retailers. Not only does this cut out middle-man costs, but it also allows for a direct relationship with the customer. There are, however, new costs that will need to be factored into online pricing, such as those involved with setting up and maintaining an e-commerce function; labour implications of cutting pieces to size and wrapping, packaging and postage costs.

101 guide – Buying and Distribution | Chapter two

What does Buying and Distribution mean to the Cheese Industry?

Cheese Transportation

The way large industrial creameries and artisan cheesemakers get their cheeses to the end consumer varies massively, largely due to the variances of buying power, economies of scale and the purchasing habits of their customers.

There may be just a couple of days or as much as a few months from leaving the cheesemakers to the cheese reaching its destination, be that a specialist cheesemonger’s, restaurant cheese trolley, supermarket chiller cabinet, or residential address. Therefore, choosing a distribution strategy that’s right for not only the business, but for each individual cheese, is vital to ensure the integrity of those cheeses is maintained.

The choice of distribution channel and their associated costs will have an impact on the profit margins of each business; so, what is affordable for one cheesemaker may be prohibitive for another. Careful consideration of the options must be given to ensure a successful business model.

The Impact of Supply Chain Management on Profit Margin

It is fair to say that the longer the supply chain, the higher the selling price a cheese is likely to have. For instance, a small cheesemaker in France may pass the cheese to an affineur, who then sells it through a national wholesale market (for example, Rungis in Paris), who sells it to a consolidator who holds it for export to a UK based national wholesaler (for example, Bradburys), who sells it to an independent cheesemonger where it is bought by a consumer. This chain is long and every link in the chain will need to make a margin which will push up the price of the cheese.

Whereas supermarkets have short supply chains, enormous buying power and little human intervention at the point of sale therefore keeping costs low.

What is the Chill Chain?

The chill chain refers to maintaining foods (cheese in this instance) under temperature control for the duration of storage, transportation and sale (including delivery for online sales). It is a science, a technology, and a process. It is a science since it requires an understanding of the chemical and biological processes linked with perishability. It is a technology since it relies on physical means to ensure appropriate temperature conditions along the supply chain. It is a process since a series of tasks must be performed to prepare, store, transport, and monitor temperature-sensitive products.

The main elements of a cold chain include:

- The lorries and vans transporting the cheese between the various stages of distribution.

- The use of insulated boxes and ice packs where cheeses are transported via non-chilled courier.

- The chilled warehouses and fridges between transportation

- The refrigerators within the retail space

The key requirements of a chill chain component are:

- Temperatures must fall between 0C and 8C.

- The chilling is continuous and unbroken between the cheesemaker and the end consumer.

What are the Components of a Cheese Distribution Chain?

All the above will influence how the cheesemaker decides to distribute their product to the end user and, consequently, price the cheese. Their individual distribution chains may consist of as many or as few stages, starting with the Milk Producer, below:

Farmer / Milk Producer

A cheesemaker may use milk from their own herd(s) or buy it in from one or several sources. The choices will depend upon the type and breed of animal, organic status, welfare standards and distance from the cheesemaker.

Dairy / Cheesemaker

From the independent, artisan to the large, industrial creameries, cheesemakers come in all sizes. Economies of scale will dictate the price of the end product and their distribution strategy.

Affineur

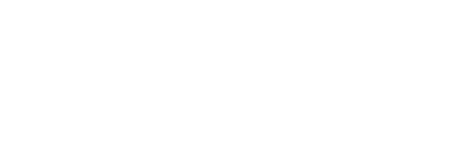

A cheesemaker may not have the space to hold onto all their cheeses before they are fully ripened and so will pass this process onto a specialist, or “affineur”. An affineur can be just that, someone that takes a young cheese and, using their expertise, ripens it to the point of selling onto someone further down the supply chain. Affineurs are sometimes the cheesemonger as well, taking the cheeses into their on-site maturing rooms, for ageing and selling on.

Producer Sale/ Farmer’s Market

Includes farm gate and online sales: effectively cutting out the “middle-man”.

Cutting & Packaging

This can be an internal process or one contracted out to a third party.

Consolidator

Consolidators hold products from many sources before dispatching them, often overseas, on behalf of large wholesalers or multiples.

Cross Docked

Where the cheese crosses from one country or region to another.

Distributor / Agent / Wholesaler

Wholesalers buy cheese from the producers, other wholesalers and importers. They come in all shapes and sizes, some that specialise in cheese (artisan and/or bulk), some which sell a wide range of products (including cheese), and some which specialise in particular markets (eg retail or food service).

Retailer

This could be a large, multi-branch supermarket, where cheese is usually sold in pre-packaged form. They typically receive their goods on pallets on lorries from company-owned central distribution hubs. Alternatively, it could be an independent retailer, eg. specialist cheese shop: these mostly use cut and serve deli-counters as their key sales service. They receive their cheeses, usually in small quantities, from specialist wholesalers or direct from producers using insulated boxes via couriers or refrigerated vans.

Food Service

Including takeaways, restaurants and canteens. Quality artisan cheeses have low penetration in mass-market food service though some service outlets will use these cheeses where quality and/or provenance is important. In this case the added kudos of a named cheese in a dish or on a cheeseboard outweighs its cost. Restaurants apply different pricing models (approx. 70%GP margin) to retailers, but have a much bigger wastage issue, particularly when offering a cheese trolley, so need to account for this.

Consumer

The end of the distribution channel, any strategy will need to consider who the target market is and the most efficient way of getting the cheese to them, whether it’s a fine-dining guest, money-conscious supermarket shopper or time-strapped professional.

101 guide – Buying and Distribution | Chapter three

What does Buying and Distribution mean to consumers?

Cheese Provenance

For consumers, knowing the provenance of their cheese has become part of its enjoyment; they want to know that the milking animals have a standard of high welfare for instance. If their preference is for artisanal varieties, they will either buy direct from the cheesemaker, visit a specialist cheese counter or look to informative packaging.

Selling Cheese Online

With today’s time-poor, cash-rich consumer looking for convenient ways of shopping, online commerce is becoming a distribution strategy not to be overlooked.

101 guide – Buying and Distribution | Chapter four

What is the relationship between the Academy of Cheese and Buying and Distribution

A Complete Cheese Training Program

The Academy of Cheese covers the topic of Buying and Distribution as a module, within each of the three levels of certification. We offer complete training programmes to all parties involved in the cheese industry; from the cheesemakers at the beginning, to the retailers at the end, including the wholesalers, buyers and food-service professionals in-between.

Aside from Buying and Distribution, the Academy’s certifications contain further modules which have relevance throughout the various components of the distribution of cheese, including:

Communicating

Communicating trains delegates on how to categorise and describe cheese, according to the way it is made. This module also contains topics on the legal requirements of packaging.

Tasting

Introduces and develops the delegate’s ability to assess and describe cheese, according to flavour, aroma and appearance. The aim of this module is for each supply-chain operator to speak a common language around cheese, which will in turn facilitate the sale thereof.

Milk Production and Cheesemaking

This module equips the delegate with a basic understanding of where and how a cheese is made, which is essential to the job of selling and distributing cheese, regardless of the size of the business.

Cheese Industry Knowledge

The differences between artisan and large-scale businesses are broken down, whilst global cheese market trends are explored.

The Cheese Library

Introduces suppliers will an in-depth knowledge of over 300 cheeses from around the world, including essential information on the make; a history around each cheese and its maker; the flavour profile of each cheese and suggestions for what to pair it with.

101 guide – Buying and Distribution | Chapter five

How is Buying and Distribution taught at Level 1,2 & 3?

Level one – the cheese distribution chain

At Level One, we look at the roles of each stage of the cheese distribution chain and learn about the importance of an effective “chill chain”.

Level two – the cheese business

Level Two looks at a cheese business from a financial perspective and delves deeper into the cost structure of the supply chain. Delegates learn the various methods of calculating costs and setting pricing strategies, whilst the impact of wastage on profitability is considered.

Level three – Supply chain and quality assurance

Level 3 breaks down the responsibilities of the supply chain from a quality assurance perspective, to ensure the safety of dairy products during its distribution and sale. Stock management policies are explored, whilst looking at the implications of wastage, VAT and international trade tariffs on profits.

101 Guide Resources

Find all the articles, video, and resources you need to study this subject.

Buying and Distribution Articles

Buying and Distribution Videos

Buying and Distribution Tools and Resources

More subjects to explore.

Cheese, obviously! We are the Academy of Cheese after all. But, our mission is much greater than just a passion for cheese. Check out the pages below to see why we need to protect, support and promote cheese, its makers and mongers, how it’s possible and what we are doing to get there.

Keep up to date with our progress. Subscribe to our blog!

Subscribe to our blogs

Get Academy mission updates delivered straight to your inbox. Subscribe to our blog and we’ll let you know what we are doing to protect, support and promote cheese, its makers and mongers as it happens.